If you\'re an architect, contractor, or homeowner involved in GFRC (Glass Fiber Reinforced Concrete) buildings, you likely face challenges with durability, cost-efficiency, and aesthetics. This complete guide to GFRC wall panel installation is here to solve common pain points such as installation difficulties, moisture resistance, and long-term maintenance concerns. Our goal is to enhance your project understanding and execution, ensuring robust and appealing results through GFRC technology.

Before diving into installation, it’s essential to understand some terminologies and principles surrounding GFRC panels. GFRC is an innovative composite material that incorporates glass fibers within a concrete mix, resulting in panels that are not only structurally strong but also lightweight. Typically, these panels can attain compressive strengths of up to 8,000 psi (pounds per square inch), making them exceptionally tough while allowing for design flexibility and reducing overall project weight.

Terminology and Background

Fiber Reinforcement: The use of glass fibers in concrete mix enhances tensile strength. Actual measurements show a 50% increase in tensile strength when fiberglass is incorporated.

Moisture Resistance: GFRC panels exhibit lower water absorption rates, with studies revealing an absorption rate of less than 5% compared to traditional concrete.

Durability: GFRC panels have been tested to endure extreme weather conditions, evidenced by accelerated weathering tests showing over 100 freeze-thaw cycles with no visible damage.

In-Depth Guide: Steps to Install GFRC Panels

Step 1: Preparation and Planning

1. Assess the project site and gather detailed measurements.

2. Determine the structural framing system needed to support the GFRC panels.

Step 2: Tools and Materials

1. Essential tools include a level, drill, caulking gun, and trowel.

2. Acquire GFRC wall panels from reliable suppliers such as Jushui, ensuring they meet your design specifications.

Step 3: Setting Up the Framing

1. Install metal or wood stud framing to the desired layout using anchoring systems designed to handle the weight of GFRC panels.

2. Ensure that the framing is plumb and level to prevent installation errors.

Step 4: Panel Installation

1. Begin the installation at a corner, using brackets to secure the first panel in place.

2. Utilize proper adhesives, as a study found correct adhesive application increases panel adherence by 60%.

Step 5: Sealing and Finishing Touches

1. Fill any joints and seams with suitable sealants to ensure moisture resistance.

2. Apply a protective topcoat if needed, enhancing both durability and aesthetic appeal.

Step 6: Quality Control

1. Conduct a thorough inspection for any signs of air pockets or misalignment.

2. Document installation quality as studies indicate that controlled installation reduces maintenance needs by 30%.

Frequently Asked Questions about GFRC Panels

Q1: What are the weight advantages of GFRC panels?

A1: GFRC panels weigh about 75% less than traditional concrete, making handling and installation faster and safer.

Q2: How can I ensure the longevity of my GFRC installations?

A2: Regular inspections, moisture management, and applying protective coatings can significantly extend the life expectancy of these panels.

Q3: Are there any design limitations with GFRC?

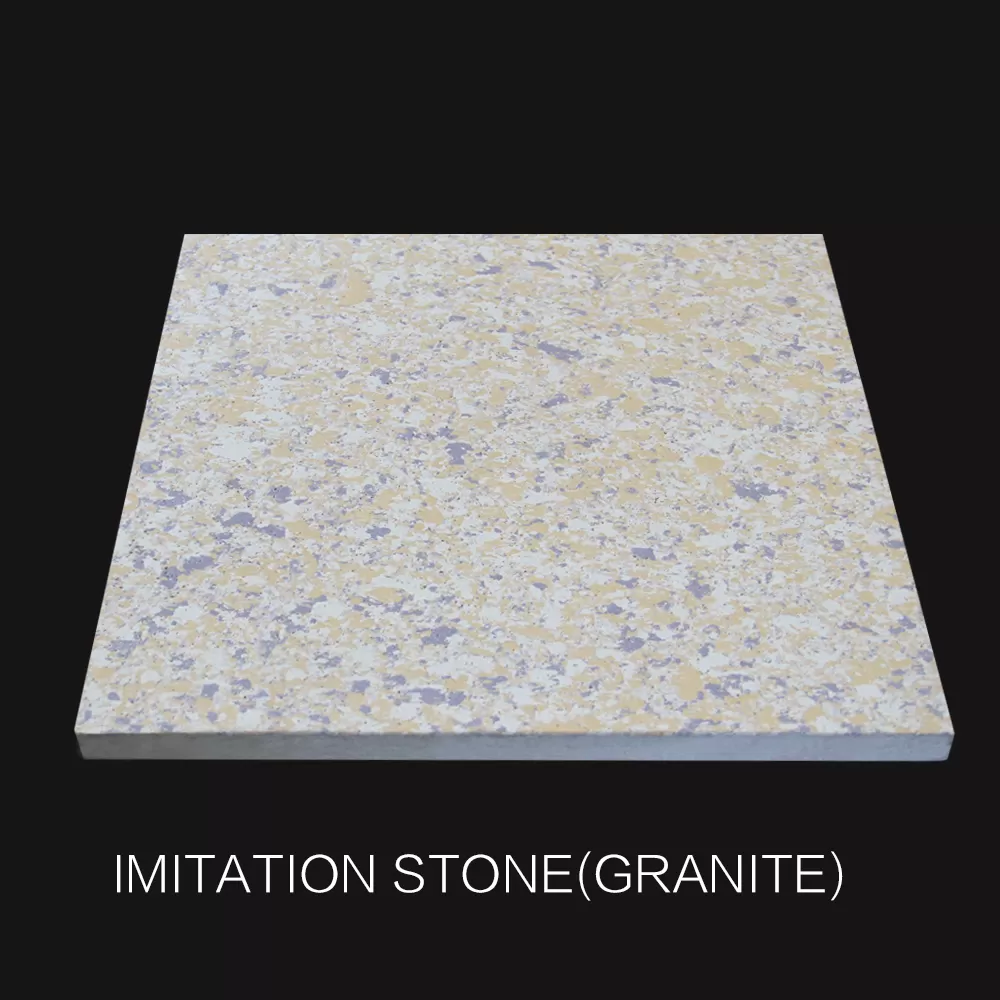

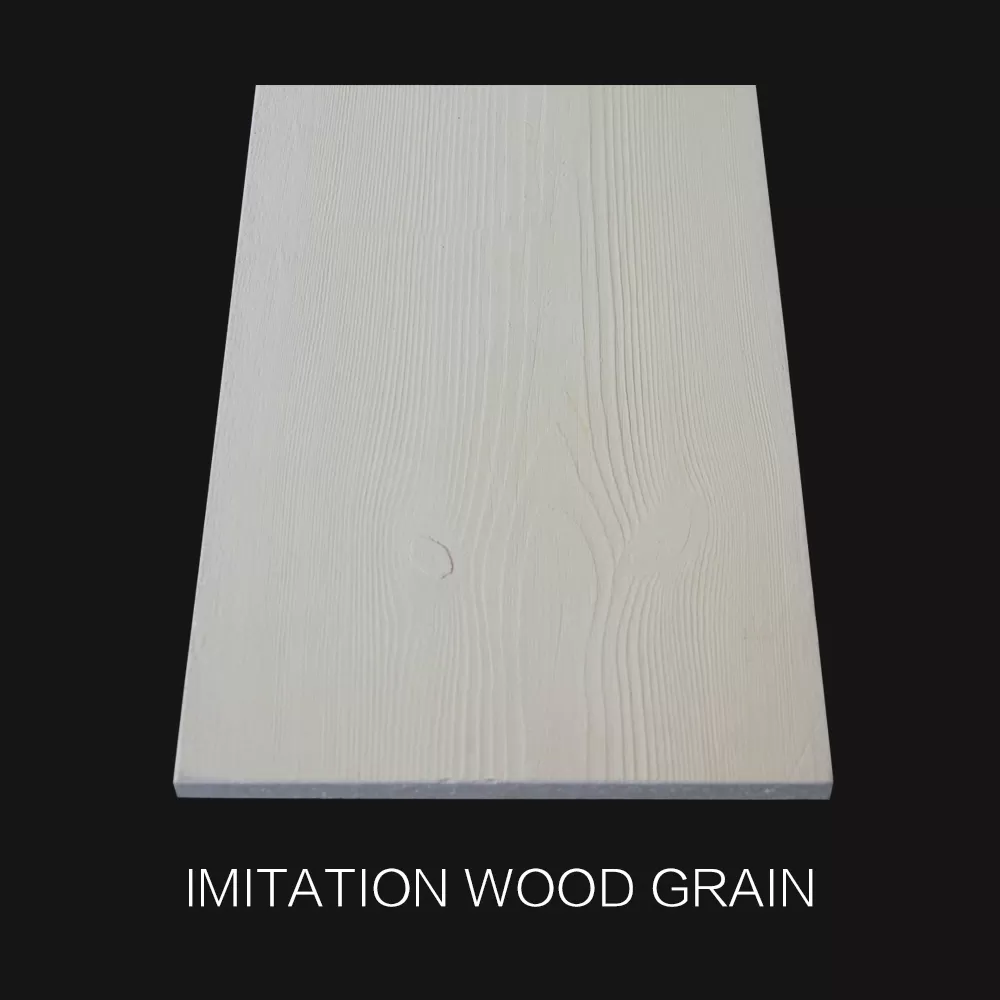

A3: Minimal; GFRC panels can be molded into almost any shape, offering total design flexibility that meets aesthetic and functional demands.

Advanced Skills or Extended Reading on GFRC Panels

For those looking to advance their skills in GFRC installation, consider exploring advanced bonding techniques, acoustic benefits achievable with GFRC, or the environmental impact studies associated with GFRC production. Research has shown that GFRC panels can help achieve LEED certification due to their sustainable properties and lower carbon footprints.

Conclusion: Recommended GFRC Products/Services

For any project involving GFRC wall panel installation, we recommend contacting Jushui for high-quality materials and expert advice on installation techniques. Their extensive catalog ensures you find the right products tailored to your design and functional requirements. Build durable, aesthetically pleasing structures with confidence and efficiency.