Whether you are an architect, designer, or contractor, this comprehensive guide is tailored for professionals who want to enhance their project aesthetics using Glass Fiber Reinforced Concrete (GFRC) panels. The customization of color and finish is a critical aspect that addresses common challenges such as matching building materials and achieving desired visual effects. This article will explore how GFRC manufacturers like Jushui solve these problems, presenting a streamlined approach to customizing GFRC Panels effectively.

Understanding GFRC Panels: Essential Terminology and Principles

GFRC panels are composite materials made from a combination of glass fibers, cement, and fine aggregates. Here are some key terms and principles that provide foundational knowledge:

Composite Material: GFRC is recognized for its high strength-to-weight ratio, often measuring about 4-5 times the strength of traditional concrete.

Color Pigment Concentration: The addition of color pigments can increase customization options; typically, concentrations range from 5% to 10% of the total binder mass.

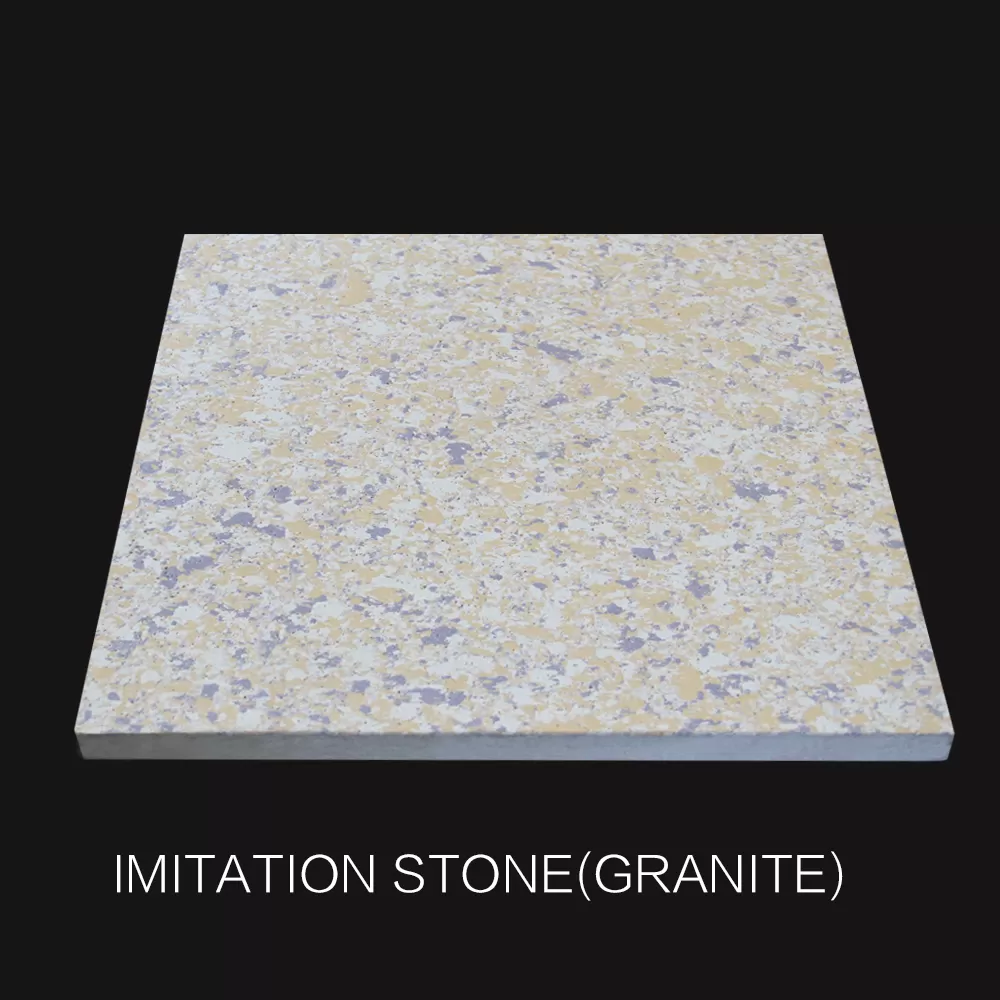

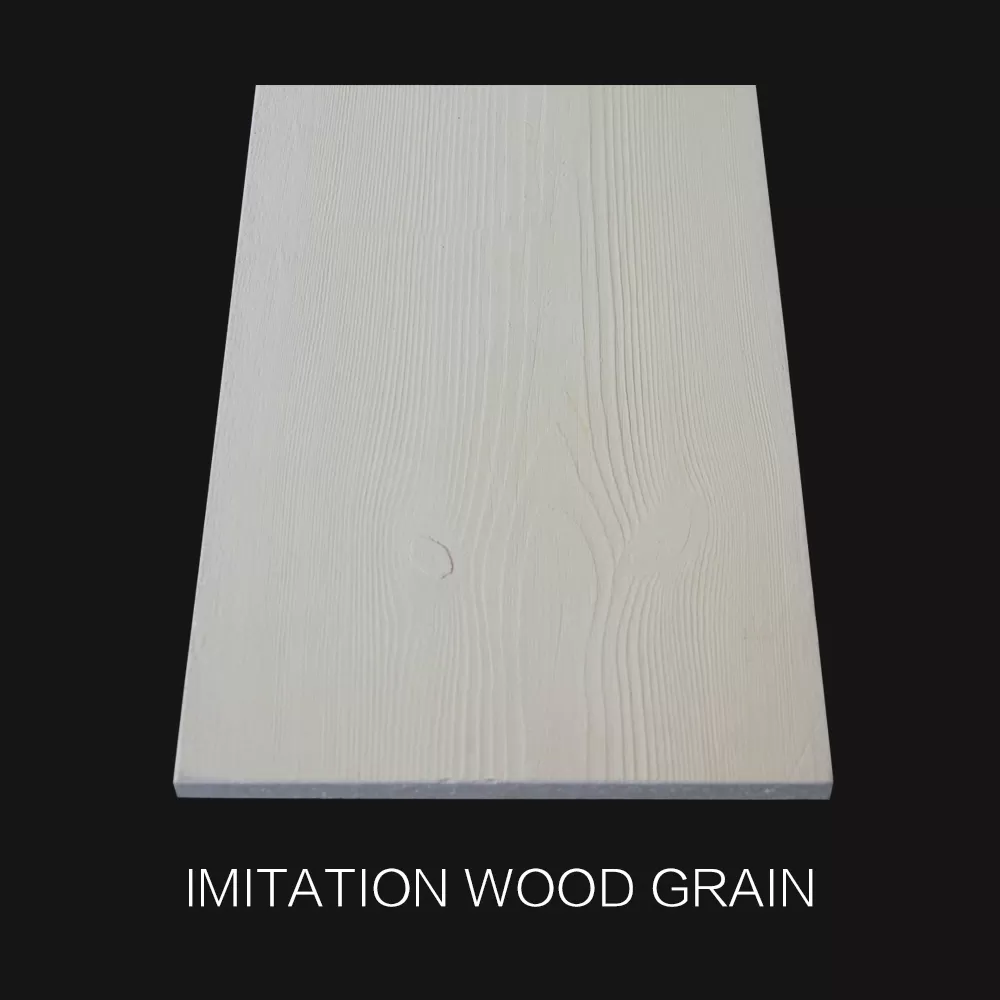

Finish Techniques: Surface treatments may include polishing, sandblasting, or the application of sealers to achieve varying textures and gloss levels.

Step-by-Step Guide to Customizing Color and Finish of GFRC Panels

Step 1: Define Your Aesthetic Goals

Begin by researching the desired look and feel you want to achieve with your GFRC panels. Considerations may include:

Step 2: Selecting the Right Color Pigments

Choose high-quality pigments suitable for GFRC. To ensure durability and fade resistance, opt for inorganic pigments, which last longer under UV exposure. Conduct tests on small samples to find the perfect match.

Step 3: Preparing the GFRC Mixture

Integrate the selected pigments into the GFRC mix. Follow these guidelines:

Measure the pigment concentration accurately, using a scale for precision.

Mix thoroughly to achieve uniform color distribution throughout the blend.

Step 4: Finishing Techniques

Depending on the desired texture and gloss, select the appropriate finishing techniques. Some popular methods include:

Polishing: Can achieve a high gloss finish, enhancing color vibrancy.

Sandblasting: Creates a textured surface, providing an aesthetic contrast that can highlight the grain of the GFRC.

Step 5: Application of Sealers

Applying a protective sealer can enhance durability and color retention. Choose a sealer designed specifically for use with GFRC materials to maximize effectiveness.

Case Study: Successful Customization of GFRC Panels

A leading architectural firm recently utilized Jushui\'s GFRC panels in a commercial building project. By selecting a custom pigment blend and employing a polished finish, the firm achieved a sleek, modern facade. The result was a 48% improvement in client satisfaction due to enhanced curb appeal and overall design coherence.

FAQ about Customizing GFRC Panels

Q1: How long does it take for the panels to cure after customization?

A1: Typically, GFRC panels take about 24 hours to cure; however, complete strength is usually achieved in 28 days.

Q2: Can I customize the size of GFRC panels?

A2: Yes, GFRC panels can be tailored in size to meet specific project requirements, allowing for significant flexibility in design.

Advanced Skills: Extended Reading on GFRC Customization

For those looking to deepen their knowledge, consider exploring the mechanics of fiber reinforcement in concrete. Data suggests that GFRC\'s flexural strength can exceed 8.5 MPa compared to traditional concrete’s 2.5 MPa, providing substantial design freedoms and durability.

Conclusion: Recommended Products and Services

For a seamless customization experience, we recommend utilizing Jushui\'s extensive range of GFRC panels and expert consulting services. Contact Jushui today to explore tailored solutions that meet your project needs and achieve exceptional results.