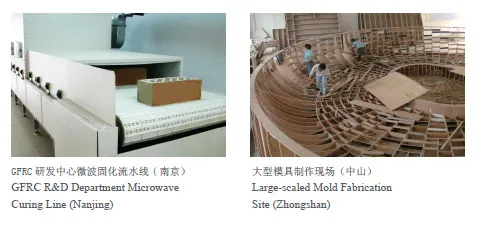

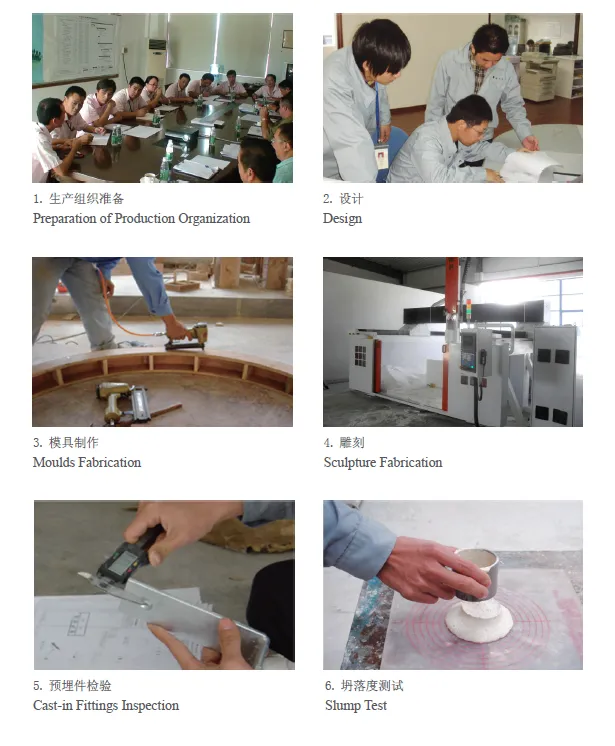

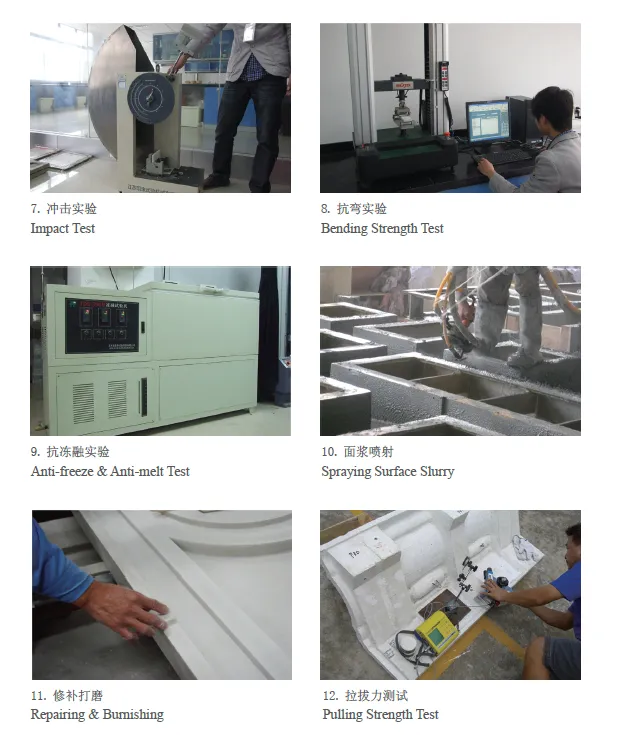

As an enterprise specialized in the GRC manufacturing and construction, Beilida, adhering to the strict scientific management, always focuses on the accurate planning and strict implementation from the project approval to production organization and preparation, from the supplier management to fine production, from process monitoring to final inspection, from product delivery to the construction organization plan and from site installation to completion inspection and acceptance. It always applies advanced technology and rigorous attitude to the whole process of production and construction.

BIM software is an important tool to analyze non-linear architectures, while Beilida BIM Design Center has successfully used the software technology to solve the manufacturing of GRC building curtain hyperboloids, positioning of three dimensional space and other technical problems.

Customization Options for GRC, GFRC, and UHPC Products

| Customization | GRC/GFRC | UHPC |

|---|

| Dimensions | Max panel size: ~3500 mm × 1500 mm | Max panel size: ~3500 mm × 1500 mm |

| Thickness: 12 mm – 60 mm | Thickness: 15 mm – 50 mm |

| Shapes: flat, curved, 3D forms, sculptural | Shapes: flat, curved, 3D forms, sculptural |

| Edge treatments: square, chamfered, rounded | Edge treatments: square, chamfered, rounded |

| Surface Finishes | Smooth, sandblasted, matte, polished, acid-etched | Smooth, polished, textured, acid-etched |

| Custom color matching (RAL/BS), integral pigments | Custom color matching, integral pigments |

| Patterns, reliefs, logos, perforations | Patterns, reliefs, logos, perforations |

| Protective coatings: UV, water repellant, graffiti | Protective coatings: UV, water repellant |

| Mechanical Properties | Compressive strength: 30–50 MPa | Compressive strength: ≥120 MPa |

| Flexural strength: ≥10 MPa | Flexural strength: ≥20 MPa |

| Water absorption: ≤8% | Water absorption: ≤0.2% |

| Fire resistance: up to Class A | Fire resistance: up to Class A |

| Density | 2000–2200 kg/m³ | 2400–2500 kg/m³ |

| Reinforcement & Fibers | Alkali-resistant glass fibers | High-performance fibers (glass, steel, synthetic) |

| Optional secondary reinforcement (mesh, fibers) | Optional secondary reinforcement |

| Thermal & Acoustic | Custom mix for insulation, sound absorption | Custom mix for insulation, sound absorption |

| Sustainability | Use of recycled aggregates, low-carbon materials | Use of recycled aggregates, low-carbon materials |

Contact Our Experts

Successful Custom Projects

We offer variety of customization options for GRC, GFRC, and UHPC products, here are some examples of projects where we provided specific solutions according to client needs:

Yinchuan Art Museum: For this project, we manufactured large GRC panels with dimensions up to 3.5 meters by 1.5 meters. The panels featured a combination of smooth and textured surfaces to meet the architectural design requirements. We used customized molds to create precise surface patterns and matched the client’s color specifications using integral pigments. The panels were produced with a thickness of 30mm to ensure structural stability while keeping the weight manageable. We provided technical support during installation to ensure proper fitting and alignment.

Wenzhou Oujiang Road Project: Situated along the Oujiang River in Wenzhou, this project features three “crystal box” buildings with facades made of high-strength UHPC precast components. CNC technology was used to produce precise geometric shapes that create dynamic wave-like patterns on the exterior. Inspired by the natural water and terrain of Oujiang, the facade achieves a distinctive three-dimensional effect. Precision mold making and on-site installation support ensured all components met design standards.

Nanchang Sales Office Project: This sales center, part of the “Bird Language and Floating Clouds” development by Vanke in Nanchang, uses 657 pieces of GRC ultra-curved panels to form the flowing facade shape. Rhino software enabled accurate 3D modeling of each panel to ensure perfect fit and alignment.

Longquanshan Forest Park High-Altitude Restaurant: Located within Chengdu’s Longquanshan Forest Park at an elevation of 745 meters, this high-altitude restaurant’s facade covers about 5,200 square meters using GRC curtain wall panels. The roof employs a concrete shell structure with a maximum cantilever of around 10 meters. The exterior integrates wood and lattice decorations to blend naturally with the environment. The project team utilized BIM modeling and close site coordination to ensure construction precision and schedule adherence.